3D-Printed Prosthetic Fingers for Women Veterans

Why miniaturize prosthetic fingers?

There are approximately 500,000 people living with minor upper limb loss in the USA [1],[2]. While the field refers to these types of amputation as ‘minor,’ it can be a severe disability, particularly if the amputation involves the thumb and/or multiple digits. Amputation can cause physical, psychosocial, and economic damage to an individual and can lead to depression, anxiety, loss of self-esteem, and social isolation [3],[4]. While the number of individuals with partial hand amputation is 10 times more than all other categories of upper limb amputation combined, the state of available technology for this underrepresented patient population is relatively poor -- especially for fitting smaller sized hands.The lack of prosthetic limb systems for women Veterans with upper limb amputation is a problem within our field. While there are several devices available for persons with partial-hand amputation, there are very few that fit women with amputation at the metacarpophalangeal (MCP) joint. Women Veterans are the fastest growing subpopulation of Veterans today increasing 29 percent between 2014 and 2019 [5]. Women Veterans account for 10 percent of the total Veteran population and are eligible to receive full range of VHA health care services including the provision of prosthetic devices [5].

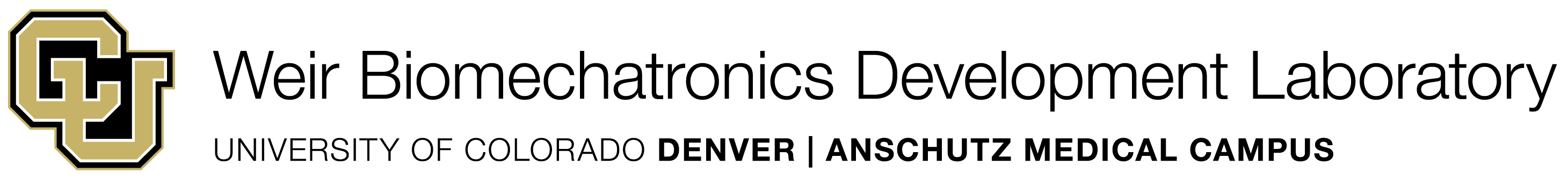

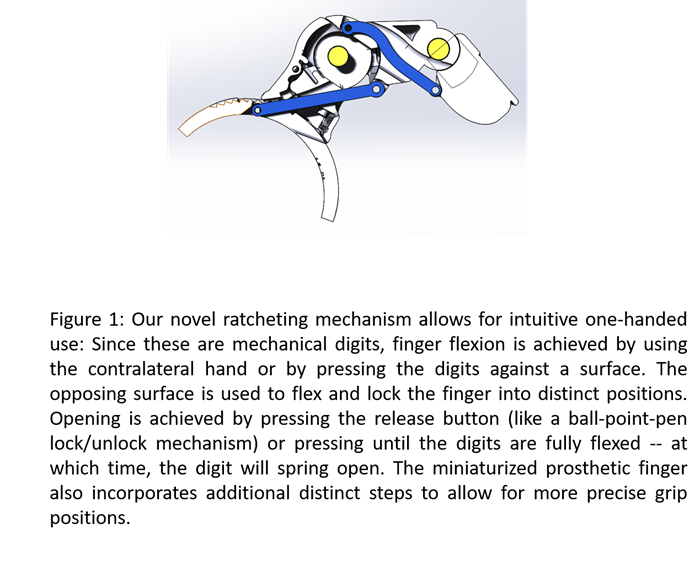

To address this need for partial fingers of smaller sizes, we are creating reliable and robust ratcheting prosthetic fingers for women, children, and pediatric populations with partial hand amputations. These 3D-printed metal prosthetic fingers will be of anatomically appropriate size and weight while maintaining functional integrity to be used on a daily basis.

Experimental Results:

In all tests of full flexion to full extension, the women’s digit met or exceeded the specification. In some cases, the digit exceeded the specification by a large margin of error. The women’s digit met the mass and length requirements of a 5th percentile female. In the most demanding test, the static load test at the distal tip of the finger, the static strength of the Women’s Digit at the distal fingertip exceeded the specification by 18 times (1,242 N compared to 66 N, 279 lbs compared to 15 lbs). The dynamic load tests were all successful in that the digits did not show any visible signs of wear, damage, or loss of function. We completed the dynamic cycle test on various sub-assemblies like the ratchet mechanism without the distal phalange to well over 250,000 cycles (300,000 cycles and counting). Three sizes (55, 65, 75) of digit have been fully cycled to 250K and are still fully functional. These results indicate that the miniaturization of the digit did not cause a decrease in mechanical performance of the ratcheting prosthetic digit.

Metrics:

Strength: Finger strength was tested in a Material Testing System (MTS) we were able to exceed the capabilities of the MTS machine without failure (>150lbs).

Weight: The finger needs to be light for comfort. The weight of the women’s digit was reduced to 25g to be appropriate for a woman with a body weight of about 90 lbs (5th% Female Wt: 88lbs). Our largest finger, the 75mm, comes in at only 25.7g, and the smallest 55mm, at 19.58g. We were able to achieve this using “light-weighting” techniques by hollowing parts using 3D metal printing developed with our direct metal laser sintering machine as well as changes in material. The current, full-sized Point Digit weighs no more than 70 g (1/8 lb) based on an estimate of the anatomical weight of a hand where the hand accounts for 0.75% of body weight. In the case of a 90 lb woman this would mean the hand would weigh ~0.675 lb. Assuming the palm is 50% of that weight, each finger and thumb would be ~0.0675 lb (~30 g). This required that we reduce the weight of the original Point Digit design by 50% while still maintaining a fully functional mechanism.

Summary:

Additionally, to promote cost effective manufacturing, we have been able to source smaller off-the-shelf parts for the internal springs and the Chicago Bolts used to hold phalanges together. We continue to improve on our design to provide the best functionality for people and hope to test in upcoming clinical trials.

References

[1] K. Ziegler-Graham, E. J. MacKenzie, P. L. Ephraim, T. G. Travison, and R. Brookmeyer, “Estimating the prevalence of limb loss in the United States: 2005 to 2050,” Arch. Phys. Med. Rehabil., vol. 89, no. 3, pp. 422–429, 2008.

[2] M. P. LaPlante and D. Carlson, “Disability in the United States: Prevalence and Causes, 1992. Disability Statistics Report 7.,” Aug. 1996.

[3] J. Davidson, “A comparison of upper limb amputees and patients with upper limb injuries using the Disability of the Arm, Shoulder and Hand (DASH),” Disabil. Rehabil., vol. 26, no. 14–15, pp. 917–923, Jul. 2004.

[4] H. Burger, T. Maver, and Č. Marinček, “Partial hand amputation and work,” Disabil. Rehabil., vol. 29, no. 17, pp. 1317–1321, Jan. 2007.

[5] U. S. G. A. Office, (2020): Veterans Health Care: Agency Efforts to Provide and Study Prosthetics for Small but Growing Female Veteran Population,” no. GAO-21-60, Nov. 2020, Accessed: Nov. 24, 2020. [Online]. Available: https://www.gao.gov/products/GAO-21-60.